For manufacturers, ensuring that bottle caps are securely sealed is essential to preventing leaks, preserving the product, and ensuring consumer satisfaction. This is where the Bottle Cap Torque Tester comes into play, offering a precise and reliable method to test the sealing strength of bottle caps. Let’s explore why this tester is essential for modern packaging and quality control processes.

What is the Bottle Cap Torque Tester?

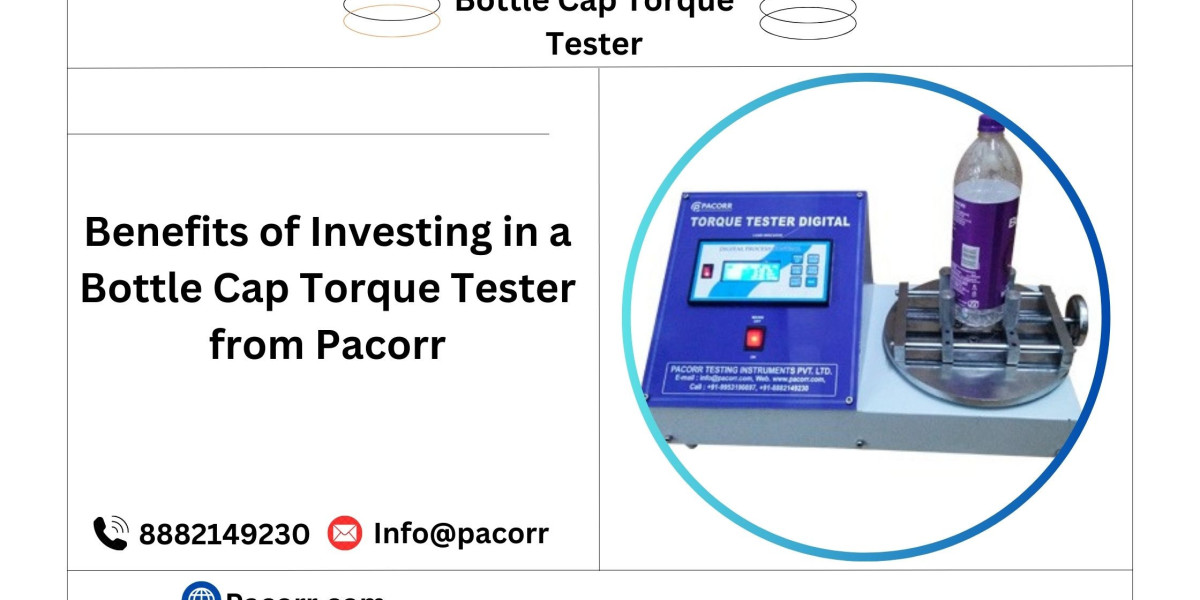

The Bottle Cap Torque Tester is a specialized instrument used to measure the torque, or rotational force, required to open a bottle cap. This tester helps manufacturers ensure that their bottle caps are neither too tight (which could be difficult for consumers to open) nor too loose (which could result in leakage or contamination). By testing the torque force, manufacturers can guarantee that the caps meet the appropriate standards for safety, convenience, and functionality.

Key Features of the Bottle Cap Torque Tester:

- High Precision Measurements

The Bottle Cap Torque Tester Manufacturers offers high-accuracy readings, ensuring that every measurement is reliable and consistent. With a wide range of torque testing, this instrument can test the torque values of various cap types, from plastic to metal, ensuring they meet quality standards. - Versatility in Testing

Whether testing standard twist-off caps, flip-top caps, or child-resistant closures, the Bottle Cap Torque Tester accommodates a broad spectrum of products, making it an indispensable tool for any manufacturer in the beverage, pharmaceutical, or food packaging industries. - User-Friendly Interface

With its intuitive design and easy-to-read digital display, the Bottle Cap Torque Tester ensures that operators can efficiently conduct tests and interpret results without hassle. The simple controls make the testing process accessible, even for those with minimal experience. - Customization of Settings

Many Bottle Cap Torque Testers allow users to set customized test parameters according to their specific requirements. This feature ensures flexibility in testing, whether you're measuring peak torque, breakaway torque, or the torque to re-seal the bottle.

Why is the Bottle Cap Torque Tester Important for Quality Control?

Bottle caps serve as the last line of defense against contamination and spoilage. Ensuring they are properly sealed is critical for maintaining the integrity of the product inside. The Bottle Cap Torque Testing plays a crucial role in the quality control process by:

- Preventing Leaks: By ensuring the appropriate torque is applied, manufacturers reduce the likelihood of leaks during transport or storage, which can lead to product loss or contamination.

- Ensuring Consumer Convenience: Consumers need to be able to open bottles without excessive force. By measuring the opening torque, manufacturers can ensure that their caps are not too tight, enhancing the user experience.

- Maintaining Safety Standards: In some industries, such as pharmaceuticals, the integrity of packaging is a regulatory requirement. The Bottle Cap Torque Tester ensures that the products meet these regulatory standards, preventing legal issues and ensuring safety.

Applications of the Bottle Cap Torque Tester:

- Beverage Industry: From bottled water to soft drinks and juices, torque testing ensures that beverage bottles are securely sealed and easy to open.

- Pharmaceutical Industry: Proper sealing of medicine bottles is crucial to prevent tampering and maintain dosage integrity. The Bottle Cap Torque Tester is used to test for both the security and ease of opening.

- Food Packaging: Whether it’s jars of sauce, spices, or canned goods, proper sealing ensures that food remains fresh and uncontaminated.

How to Use the Bottle Cap Torque Tester: Using the Bottle Cap Torque Tester price is straightforward, and here’s a general guide:

- Set the Parameters: Choose the test settings (e.g., torque range, test type).

- Place the Bottle: Secure the bottle in the machine’s testing station.

- Conduct the Test: Activate the machine to measure the torque required to open the cap.

- Analyze the Results: Review the data displayed on the screen, and compare it to the set standards.

Conclusion:

The Bottle Cap Torque Tester is an indispensable tool for quality control in the packaging industry. By ensuring the right amount of torque is applied to bottle caps, manufacturers can prevent leaks, ensure consumer satisfaction, and comply with safety regulations. At pacorr.com, we offer high-quality Bottle Cap Torque Testers designed to meet your testing needs. Contact us today to learn more about how our instruments can improve your product quality and packaging efficiency.

FAQ Section:

- What is torque testing on bottle caps?

Torque testing on bottle caps measures the amount of force required to open a cap. This ensures that the cap is neither too tight nor too loose, which is crucial for preventing leaks and ensuring ease of use for consumers. - Why is torque testing important for packaging?

Torque testing is important to ensure that bottle caps meet industry standards for security, safety, and ease of use. It ensures that Bottle Cap Torque Machine Price are sealed tightly enough to protect the product but not so tight that they are difficult to open. - How does the Bottle Cap Torque Tester work?

The Bottle Cap Torque Tester measures the amount of rotational force required to open a bottle cap. It provides precise readings that help manufacturers maintain consistent sealing practices and ensure quality control. - Can the Bottle Cap Torque Tester be used for different types of bottle caps?

Yes, the Bottle Cap Torque Tester is versatile and can test a variety of bottle cap types, including twist-off, snap-on, and child-resistant caps. Its adaptability makes it ideal for use across different industries. - Is the Bottle Cap Torque Tester easy to use?

Yes, the Bottle Cap Torque Tester is designed for ease of use with intuitive controls and a user-friendly interface. The clear digital display ensures operators can easily read and interpret the results.